|

Plastic or Composite Fuel Tanks

|

| Click picture to enlarge |

Unlike

the classic ’57 Chevy or the luxury Lincolns and Cadillacs of yesterday, auto designers today are forced to meet many

safety, economic, and environmental standards. These three standards affect most every part of the vehicle including the fuel

system.

Safety:

One of

the greatest threats to human survival in automobile collisions is fire. Ruptured fuel tanks, filler tubes, and fuel lines

are major factors in post crash fire situations. Once fuel spillage has occurred, the likelihood of that fuel coming into

contact with an ignition source is almost a sure thing and once ignited not more than twenty seconds are available for escape

from a burning automobile, even with protective fire gear (as we will later see).

|

| click picture to enlarge |

From 1968

to 1972 the NHTSA researched and analyzed auto fire causes, after seeing the disasters from the Ford Pinto gas tank design.

During that four year period nearly 9,000 people burned to death in flaming wrecks.

Tens of thousands more were badly burned and scarred for life.

The ‘73-‘87 Chevy PU gas tank design cost GM more than $500,000,000 in law suits, and is

considered the worst cause of automotive design related deaths in history, with a list of victims names over 15 pages long.

Many of our law enforcement friends have been killed or injured in the Crown Victoria crashes due to the gas tank design, and the list goes on and on.

Economics:

In an effort to relieve the gas and oil crises automakers are forced to cut every ounce of weight possible

to increase fuel mileage.

Environmental:

In the

early 1970s environmental standards forced automakers to change their fuel systems drastically, earlier vehicles used leaded

gasoline, and the vapors were simply vented through a small hole in the gas cap into the atmosphere. The new standards forced

them to use unleaded gasoline and sealed fuel systems that would no longer vent into the air. Since 1970 all fuel systems

are vented through a charcoal filter system. The vapors are then routed back into the engine to be burned before being released

to the atmosphere; this is called evaporative emission control.

With these

vapors being in a sealed system and constantly changing pressures as they expand and contract with the change in temperatures,

some part of the system must be flexible.

Plastic or Composite Fuel Tanks

|

| Click picture to enlarge |

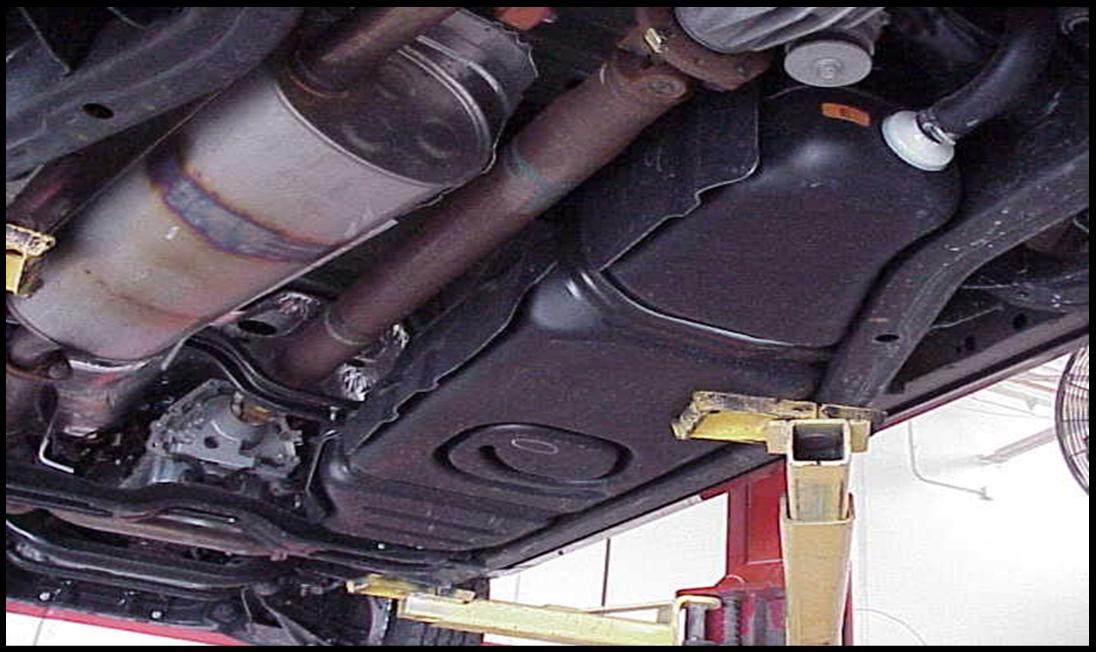

Today’s plastic gas tanks have become the answer

to all three of these problems. The polyurethane and polyethylene used in most of these tanks is six layers thick, making

them highly resistant to punctures. It’s also flexible allowing for expansion of vapors and bending during a crash.

Most firefighters know the most vulnerable part of a metal tank is the seams, being molded these tanks are seamless. Also

being molded they have no edges to snag on and rupture, when being pushed forward in a crash. By federal standards all edges

and corners must be rounded. Economic wise the six layered polyethylene tank is still lighter than the same size metal tank.

As we seen in the introduction, today’s vehicles,

(even the gas tanks), are literally built to wreck but as we will see here not one is

built to burn.

The HIGH-DENSITY POLYETHYLENE

(HDPE) and POLYURETHANE used in these tanks melts at very low temperatures, ranging from 266-284 degrees and

with these tanks holding from 15 – 28 gallons of gas, a person can only imagine the results if one dropped its heated

load under a burning vehicle. Yet today we are still teaching firefighters to approach the vehicle diagonally to the corner,

putting them right in the ring of fire, if this was to happen.

Is

it time to change out training Yet?

Let's look at what can happen.

|

| Click picture to enlarge |

Level Ground:

This is a personal experience that I had. This is

the same 2004 Ford Ranger we seen in the airbag section where the airbags deployed in the mop up stages. This tank

dumped about ten gallons of gas on the ground, creating a circle of fire about 25 feet in diameter. We have two manufacturers that supply us with special suppression agents

for demonstrations in our classes, these products are both extremely good. We burn a pile of ten car tires until they

are boiling with black smoke, then using these agents put them out with a 2 ½ gallon water can extinguisher in about eight

seconds and lay your bare hand on the tires. We used one of these on this tank and it still flared up seven times. In investigating

this we found that because of the shape and location of the tank there were pockets of fuel that could not be reached with

the extinguishing agent and therefore were not affected by it. Firefighters must be aware that this situation is going to

exist with every tank. As plastic begins to melt it will sag forming pockets, each of these pockets will hold a certain amount

of fuel until it melts through and being mounted under the vehicle and inside the frame work, it is impossible to reach every

part of the tank with any type of extinguishing agent.

Down hill incline:

www.cdc.gov/niosh (NIOSH fatality report)

On August 8, 1999,

three volunteer fire fighters were burned, one (the victim) critically, while trying to control a Recreational Vehicle (RV)

fire beside a single-family dwelling. The victim died 8 days later due to full thickness burns (third degree) over 96% of

his body. Two volunteer fire departments responded to this incident: Volunteer Fire Department #1 (VFD #1) with Engine 1,

staffed by a driver/operator; and Volunteer Fire Department #2 (VFD #2) with Engine 2, staffed by a driver/operator and one

fire fighter (the victim) who rode as the passenger in the cab of Engine 2. Another fire fighter from VFD #2 responded to

the scene in a privately owned vehicle (POV). Engine 1 arrived on the scene and was positioned in the driveway of the dwelling.

The driver/operator used the booster line to protect the exposed side of the dwelling and then tried to control the RV fire.

Engine 2 arrived less than 5 minutes later and also took a position in the driveway. While fire fighters from Engine 2 attempted

to place in service the pre-connected 1½-inch attack line from the rear hose bed of the apparatus, the RV’s gasoline

tank ruptured, releasing about 50 gallons of gasoline. The gasoline ignited, and the burning fuel spilled down the inclined

driveway. All three members of VFD #2 suffered thermal injuries.

Video - Good example on down hill incline

Inside the garage:

Missouri City, Tx.

Four Missouri City firefighters entered a garage from a side door to battle a vehicle fire inside, within

seconds the plastic gas tank dumped its fuel in the floor engulfing all of them in flames.

(Click here to see the live interview I had with the chief).

Pressurized Plastic

Fuel Line

As bad

as they are, these tanks are not the only dangers the fuel system presents us with. As was mentioned before, these are sealed

systems that do not vent into the air.

Unlike

the old carburetor with a chock, today’s vehicles are fuel injected and must have pressurized gas available at all times,

in order to start. These vehicles are equipped with electric fuel pumps inside the tank. Once the fuel passes the pump into

the fuel lines it can not return and until the injector on the engine is mashed to a certain point that fuel can not enter

the return lines. Therefore pressurized gas is held in the fuel lines at all times. Most of these fuel lines are also made

of plastic and run under the vehicle from the tank in the rear all the way to the engine in the front and contain from 15-95

psi of pressure at all times.

Ford Crown Victoria has had an extreme problem with their gas tanks exploding

in a high speed rear collision. They have developed a fire suppression system that is available on the Police Interceptor.

Here is some information that will help you deal with the FSS equipped cars.

Ford FSS system

Actual Incidents

Ab. Canada; Had a plastic gas tank on a Ford Aerostar Van give away about 15 sec. after

I arrived on scene. Of course I was command that weekend so all I had was a 1/2 ton with a 10# ABC in the back  Pucker factor told me to wait until the boys in the big red truck with the copious amounts of wet stuff arrived. Pucker factor told me to wait until the boys in the big red truck with the copious amounts of wet stuff arrived.

Wilmington nc; We had a plastic gas tank rupture in a jeep cherokee fire. Of course

they had just filled up and were in the middle of a university parking lot with nary a plug in sight. Two engine companies

and some foam later the fire was out but everyone got a good lesson in plastic fuel tanks. They really suck in a fire.

Virginia; This would be about 3 winters ago now, but Malahat was toned to a truck on

fire, during one of our lovely winter storms. Anyhow, the veh involved as a late model Dodge Dakota p/u. The box was full

of funiture and much of the contents, and rear of the cab were burning well when we arrived. We lost the truck in the end.

However:

During that fire we also went through about 2500 gal of water because initially unbeknownst to us, it had a polywhosit

tank that had been compromised. Everytime it looked like the fire was overhauled it would start up again. It took some unloading

of the stuff in the back and the use of a chop saw to cut through the box to expose the fuel tank. I was running the pump

through this incident which was made even more interesting for the fire crews because of the ice and snow on the road surface,

and that it was at the apex of a curve, with a high camber. Trying to push 200 psi through the 1.5 for good foam made for

a long day on the line. Firefighter26 was on the line, and could add more to this story.

Fortunately it did not rupture

at any time. But it did give a good lesson on 3 dimentional fires.

Plymouth, WI These plastic tanks suck, no sugar coating it. I've

had more than one melt, and spill their contents. One in recent memory, that one got interesting really, really fast.

Just another hazard to be aware of, especially if it's a late model. Just another hazard to be aware of, especially if it's a late model.

|