|

Roll-Over Protection Systems

This page includes:

- Roll-over protection airbags

- Flip-up type full roll-bars

- Pop-up type roll-bars

- EMS concerns

Like all safety restraint systems; The rollover

protection system must have a sensor to determine that there is a crash.

|

| Click picture to enlarge |

The rollover sensor is a little more complex than

the normal crash sensor. The Electronic Rollover Sensor provides additional protection by measuring whether the vehicle is

tilting, how fast the lean angle is changing and whether the combination means the vehicle might be headed for a rollover.

The sensor ( inclinometer) is designed

to measure the lateral and vertical acceleration, vehicle speed and roll rate to predict an impending rollover. When the sensors

detect a potential rollover, the control module triggers the curtain airbags and seat belt pre-tensioners.

An onboard computer protects against accidental deployment

by comparing the tilt angle and rate-of-roll, determining whether the vehicle is going to recover, or whether a

roll is inevitable. If the vehicle is going to roll, the system not only deploys, but also matches deployment speed to the

event. A high-speed curb launch will trigger a faster deployment than a corkscrew roll on an embankment.

|

| Click picture to enlarge |

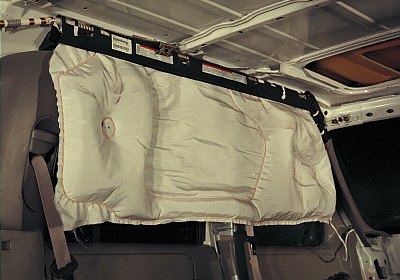

These sensors work in conjunction with a new style

curtain airbag.

Like all curtain airbags, the new "Safety

Canopy" airbags are hidden behind the headliner. These were first introduced in the 2002 Explorer and extended from

the A-pillar to the C-pillar. Today another section has been added to protect the third row seat area and these are now found

in most all Ford SUVs, Vans and some

cars, such as the 2008 Taurus and Sable.

Once these bags deploy, tethers located on

the bottom corners of the bag, lock them in place to prevent occupants from being ejected.

Caution! During cutting

operations, rescuers should be aware that with the addition of the third row section, they may find two compressed gas inflaters

on both sides of the roof rail instead of one. These must be visually exposed before cutting operations begin.

Warning! These airbags

have a controlled deployment speed and may deploy much faster than other airbags. The deployment zone is from the roof rail

to the bottom of the window, the full length of the vehicle and the bag is about 5 inches thick.

Like other curtain airbags, if the bag is deployed

the rescuer can simply cut the tethers and bag, to remove them out of their way. These are all single stage and can not

deploy a second time like frontal airbags.

The bag itself is also quit different than

most airbags. Most airbags depend on thermal expansion for volume. In simple terms, the nitrogen in a normal deployment

is heated, causing it to expand and fill the bag. But when the gas within the bag cools and begins to escape through

the porous material of the bag, the bag loses volume rapidly, causing it to deflate.

These airbags use a cool-gas inflator

and low-porous bag materials. The gas is cooler; so there is less shrinkage as there would be with the heat loss

and the airbags are much less porous, so they retain their volume longer. They are designed to remain inflated for up to 6

seconds, or approximately the time it takes an average vehicle to roll over a few times.

Another difference between these and other airbags,

is that the bag is folded inside the module much different. These use what is called "Roll Fold Technology". These bags

actually roll down between the window glass and the occupant, rather than expanding like an accordion, the way other

airbags do. This rolling affect allows these curtains to deploy even if the occupant is out of position. The bag will actually

roll between their head and the glass and set them upright in the seat.

The "Safety Canopy" also serves a twofold purpose.

In the event of a side impact collision, the control module will override the rollover sensor and allow the side impact

sensor to deploy these, the same as a normal side curtain airbag.

Warning! Like the curtain airbags, never

lean through the window when approaching the vehicle. These deploy straight down about 18 inches, or to the bottom of the

window and are capable of snapping a person's neck.

Video --- Watch the 180 lb dummie's feet

Rollover Protection System (ROPS)

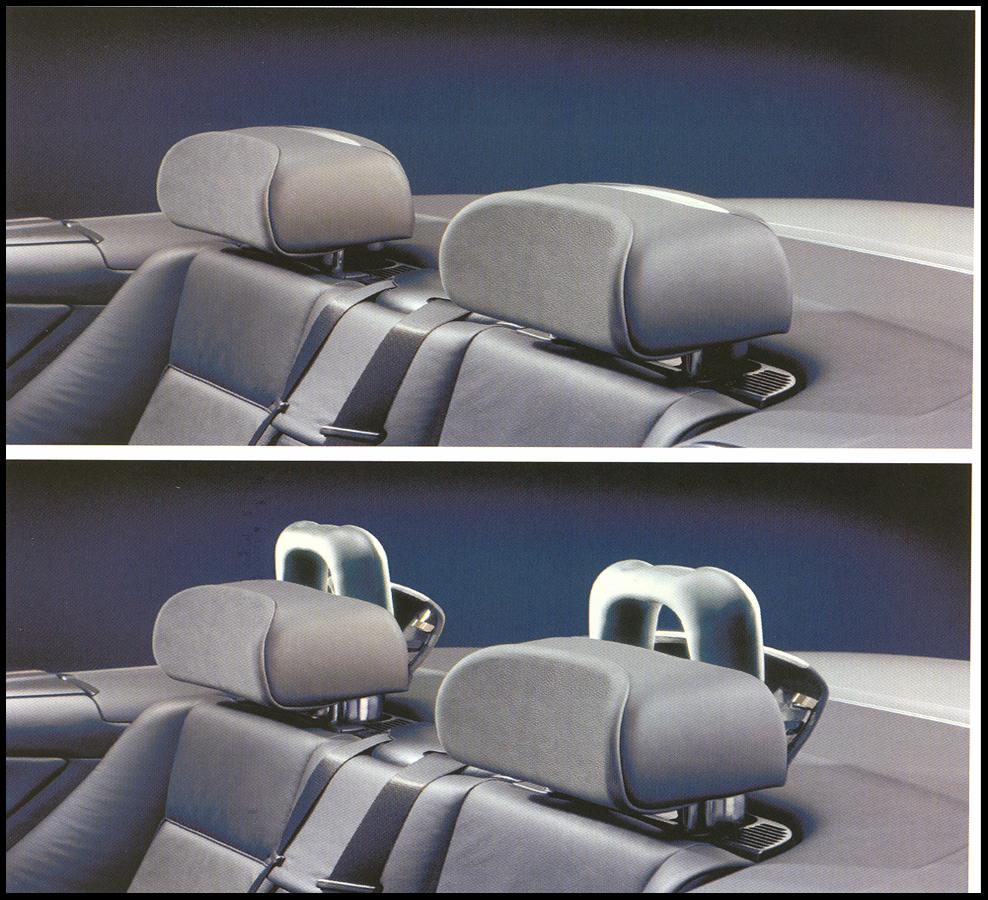

One of the earliest ROPS systems was introduced

by Mercedes in 1986. There are two types of deployable roll bars, for lack of a better name, the flip-up type and

the pop-up type. These are considered to be the flip-up type.

The flip-up type look much like a conventional

flat fixed rollbar, but unlike the fixed rollbar, deployable rollbars are concealed until activated. Then they will flip

up in less than three tenths of a second, much the same as a deploying airbag. These systems are hydraulically deployed. Once

deployed they are locked into place.

The flip-up type is used on the Mercedes two

seat roadster.

click here to play video

. .

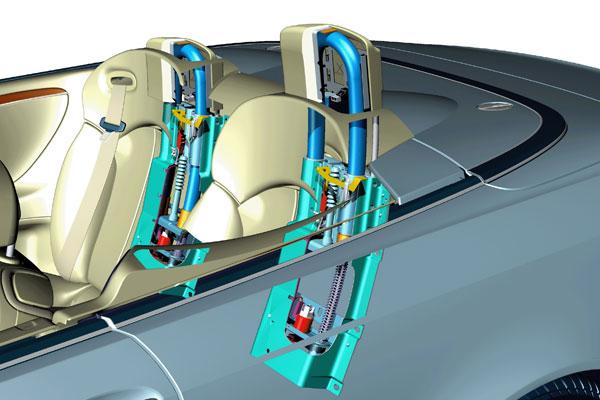

Today there are many types of pop-up rollover

protection systems.

Some of the Mercedes pop-up systems are also hydraulically

deployed. While many other systems are spring

loaded and operated by an actuator latch devise.

Actuator---See animation of latch devise.

These systems are activated by an inclinometer used to

sense vehicle inclination and lateral acceleration. There is also a G-sensor that detects vehicle weightlessness if the vehicle

becomes airborne. These sensors send information to a control module the same as SRS senors do. The control module then determines

when to deploy the roll-bars. Certain limitation must be met before the control module will actuate the deployment. It

will only deploy the roll-bars in the following scenarios:

- When the vehicle approaches a lateral angle limit

of 62 degrees.

When the vehicle experiences a lateral acceleration

of approximately 3 Gs.

- When the vehicle approaches it's longitudinal angle

limit at approximately 72 degrees.

- When a combination of longitudinal acceleration

and longitudinal angle would cause the vehicle to roll over in the forward direction.

When the vehicle becomes airborne

and achieves weightlessness for at least 80ms.

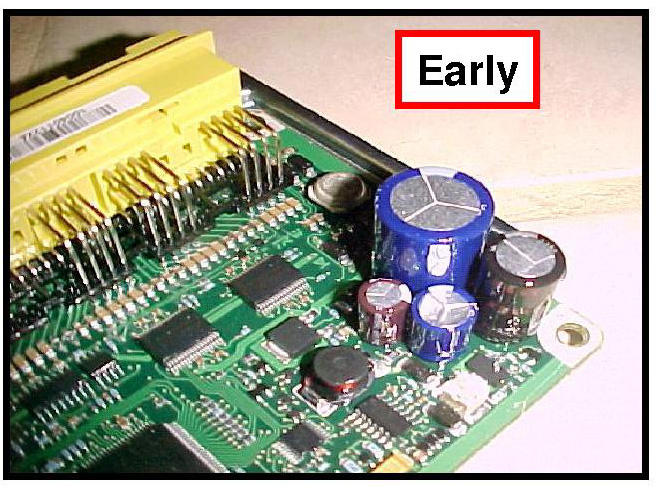

Warning! The control

module is just like the ones used with SRS systems. They contain capacitors that supply power to the system in case the battery

is destroyed in the crash.

The average capacitor drain time is 10 seconds.

The pop-up bars are individual units mounted behind

the rear seats.

See --- Watch as Jaguar's bars pop-up.

Some are visually obvious

Others pop-up through holes behind the rear head rest.

Rescuer and EMS Concerns

Warning! EMS personnel should never lean

over the back of a convertible as in holding C-Spine on an occupant. This would put the rescuer's head right over the undeployed

roll-bar.

Many of the vehicles that are equipped with

these systems also have their batteries mount in hidden areas, such as the trunk or under the seats. Other times being roof

resting the batteries are not immediately accessible.

Rescuers must stay out of the deployment zone in

these cases. The deployment zone is 20 inches straight up from the bars.

Special considerations for the Mercedes hydraulic

types:

These systems have a manual deployment switch mounted

on the dash. If the roll-bar is not deployed, rescuers must get the power shut down immediately. If the battery is not accessible,

rescuers can manually deploy the bar by using the switch. The manual deployment is much slower than a normal deployment and

will make the bar safe to work around.

|